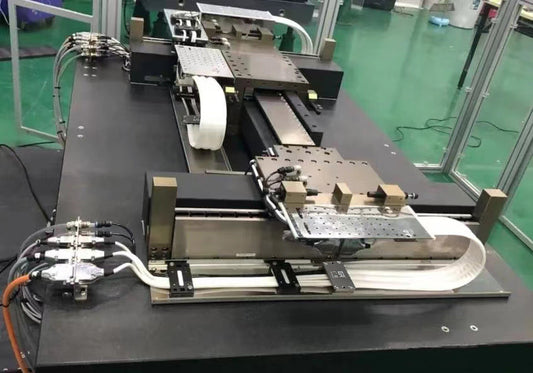

When it comes to dust-free drag chains, there are various factors to consider in order to ensure optimal performance. One important consideration is whether or not a keel is necessary. In this blog post, we will explore how to determine whether a dust-free drag chain needs a keel or not, and why this decision is crucial for the overall efficiency of the system.

Why is a keel important?

A keel is a structural element that is attached to the bottom of a dust-free drag chain. Its primary function is to provide stability and prevent the chain from sagging or swinging excessively during operation. This is particularly important when the chain is carrying heavy loads or when it is subjected to high speeds or accelerations.

Factors to consider

When determining whether a dust-free drag chain needs a keel or not, there are several factors that need to be taken into account:

1. Load capacity

The load capacity of the drag chain is a critical factor in determining whether a keel is necessary. If the chain is expected to carry heavy loads, a keel is highly recommended to provide the necessary support and stability.

2. Speed and acceleration

The speed and acceleration at which the drag chain will be operated also play a role in the decision. Higher speeds and accelerations can cause the chain to swing or sag more, making a keel essential to maintain stability and prevent damage.

3. Length of the chain

The length of the drag chain is another important consideration. Longer chains are more prone to sagging, especially when carrying heavy loads. In such cases, a keel can help to distribute the weight more evenly and prevent excessive sag.

4. Environmental conditions

The environmental conditions in which the drag chain will be operating should also be taken into account. If the chain will be exposed to vibrations, extreme temperatures, or other challenging conditions, a keel may be necessary to ensure its stability and longevity.

Consulting the experts

While considering these factors is important, it is always recommended to consult with experts in the field. They can provide valuable insights and guidance based on their experience and knowledge. They will be able to assess the specific requirements of your application and determine whether a keel is necessary for your dust-free drag chain.

Conclusion

Determining whether a dust-free drag chain needs a keel or not is a crucial step in ensuring the optimal performance and longevity of the system. By considering factors such as load capacity, speed and acceleration, chain length, and environmental conditions, you can make an informed decision. Remember to consult with experts to get the best advice tailored to your specific application. With the right approach, you can ensure that your dust-free drag chain operates smoothly and efficiently.