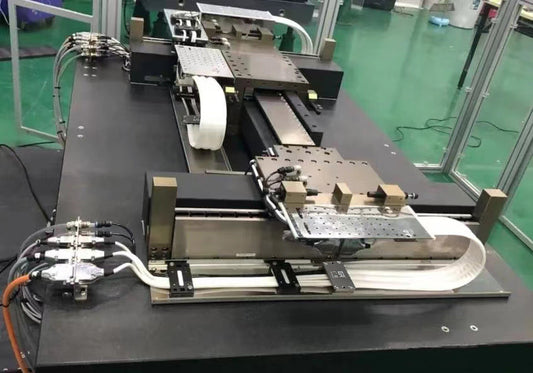

In cleanroom environments, dust-free drag chains (also known as cleanroom drag chains or dust-free cable carriers) play a crucial role in protecting and guiding moving cables. An often overlooked design detail is whether to include a backbone (dragon bone) or extrusion rail to enhance stability and limit flexing. Here, we present a concise, evidence-based overview to help engineers decide when a backbone is appropriate, with practical guidelines for XY and Z axis configurations.

What is a backbone in cleanroom drag chains?

- A backbone or extrusion rail is an auxiliary structural element added to a drag chain system.

- Its primary functions are twofold: (1) provide additional support to resist bending and sagging, and (2) restrict the maximum deviation or flutter of the moving chain, thereby maintaining orderly cable pathways.

- By stabilizing the drag chain, the backbone helps preserve cleanroom integrity and reduces the risk of cable damage or tangling in demanding applications.

Guidelines for when to consider using a backbone

- XY axes with long travel: If the installation stroke along the XY axes exceeds approximately 600 mm, adding a backbone is advisable. Longer travels increase the tendency for the drag chain to flex or bow, which can compromise cable routing and dust containment.

- Z axis and unconventional orientations: For the Z axis, or non-standard mounting orientations such as lateral (side-lying) or inverted installations, a backbone can be beneficial even at shorter stroke lengths (around 300 mm). These orientations introduce additional moments and asymmetrical loading, which can amplify chain deflection.

- Site-specific considerations: While the 600 mm (XY) and ~300 mm (Z or nonstandard) thresholds provide practical benchmarks, the final decision should account for on-site conditions. Factors include load, acceleration, operating speed, cabling bundle diameter, routing complexity, and the required level of dust containment.

Why a backbone matters in cleanroom environments

- Stability and reliability: A backbone reduces lateral deflection of the drag chain, contributing to smoother cable movement and less wear over time.

- Dust control: A more rigid chain path minimizes gaps and irregularities where particulates might escape, reinforcing the dust-free performance essential in cleanrooms.

- Longevity and maintenance: By maintaining consistent cable trajectories, the backbone can lower maintenance needs and extend service life in demanding cleanroom applications.

How to assess and implement

- Evaluate travel length and orientation: Measure the actual stroke and installation orientation (XY travel, Z travel, and any nonstandard mounting).

- Determine dynamic loads: Consider acceleration, deceleration, and the maximum cable bundle diameter to estimate bending moments on the chain.

- Consider environmental requirements: In ultra-clean or ISO class environments, construct the backbone from compatible materials and ensure it does not introduce contaminants or outgassing.

- Collaborate with the supplier: Request a technical assessment or a design recommendation from your cleanroom drag chain manufacturer, providing travel, load, and routing details to determine if a backbone is warranted.