Maintaining Dustfree Operation of Drag Chain Cable Carriers

Share

Dustfree Drag Chain Cable Carrier Operation

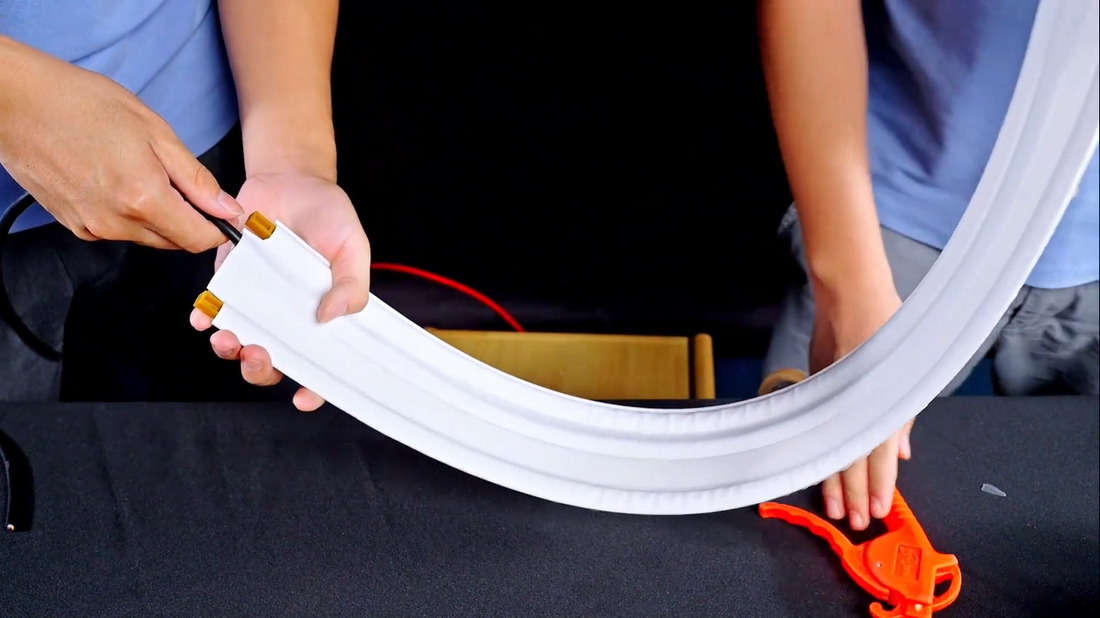

Drag chain cable carriers are essential components in various industries as they are designed to protect and guide cables and hoses for machinery and equipment. One common problem that can arise with drag chain cable carriers is the accumulation of dust and debris, which can hinder their operation and potentially cause damage to cables and hoses.

To ensure smooth and efficient operation of drag chain cable carriers, it is important to maintain a dust-free environment. Here are some steps you can take to achieve this:

1. Regular cleaning: Regularly clean the area around the drag chain cable carrier to remove any dust and debris that may have accumulated. This can be done using a vacuum or compressed air.

2. Proper installation: Ensure that the drag chain cable carrier is installed correctly and securely in place. This will help prevent dust and debris from entering the carrier and causing blockages.

3. Use appropriate covers: Consider using covers or shields to protect the drag chain cable carrier from dust and debris. These covers can be made of plastic or metal and are designed to keep out unwanted particles.

4. Lubrication: Proper lubrication of the drag chain cable carrier can also help prevent dust and debris buildup. Use a lubricant recommended by the manufacturer to ensure smooth operation.

5. Inspection: Regularly inspect the drag chain cable carrier for any signs of damage or blockages caused by dust and debris. Address any issues promptly to prevent further damage.

By following these steps, you can help ensure that your drag chain cable carrier operates efficiently and effectively in a dust-free environment. This will not only extend the life of the carrier but also protect your cables and hoses from damage, ultimately saving you time and money in the long run.

Drag chain cable carriers are essential components in various industries as they are designed to protect and guide cables and hoses for machinery and equipment. One common problem that can arise with drag chain cable carriers is the accumulation of dust and debris, which can hinder their operation and potentially cause damage to cables and hoses.

To ensure smooth and efficient operation of drag chain cable carriers, it is important to maintain a dust-free environment. Here are some steps you can take to achieve this:

1. Regular cleaning: Regularly clean the area around the drag chain cable carrier to remove any dust and debris that may have accumulated. This can be done using a vacuum or compressed air.

2. Proper installation: Ensure that the drag chain cable carrier is installed correctly and securely in place. This will help prevent dust and debris from entering the carrier and causing blockages.

3. Use appropriate covers: Consider using covers or shields to protect the drag chain cable carrier from dust and debris. These covers can be made of plastic or metal and are designed to keep out unwanted particles.

4. Lubrication: Proper lubrication of the drag chain cable carrier can also help prevent dust and debris buildup. Use a lubricant recommended by the manufacturer to ensure smooth operation.

5. Inspection: Regularly inspect the drag chain cable carrier for any signs of damage or blockages caused by dust and debris. Address any issues promptly to prevent further damage.

By following these steps, you can help ensure that your drag chain cable carrier operates efficiently and effectively in a dust-free environment. This will not only extend the life of the carrier but also protect your cables and hoses from damage, ultimately saving you time and money in the long run.