In the fields of automated production machinery and robots, reciprocating cyclic motion is a common action. During the movement of the equipment, the built-in cables, oil pipes, gas pipes, water pipes, etc. mainly rely on drag chains for traction and protection. So, how should we choose a tracked plastic drag chain? What are the scope of its application?

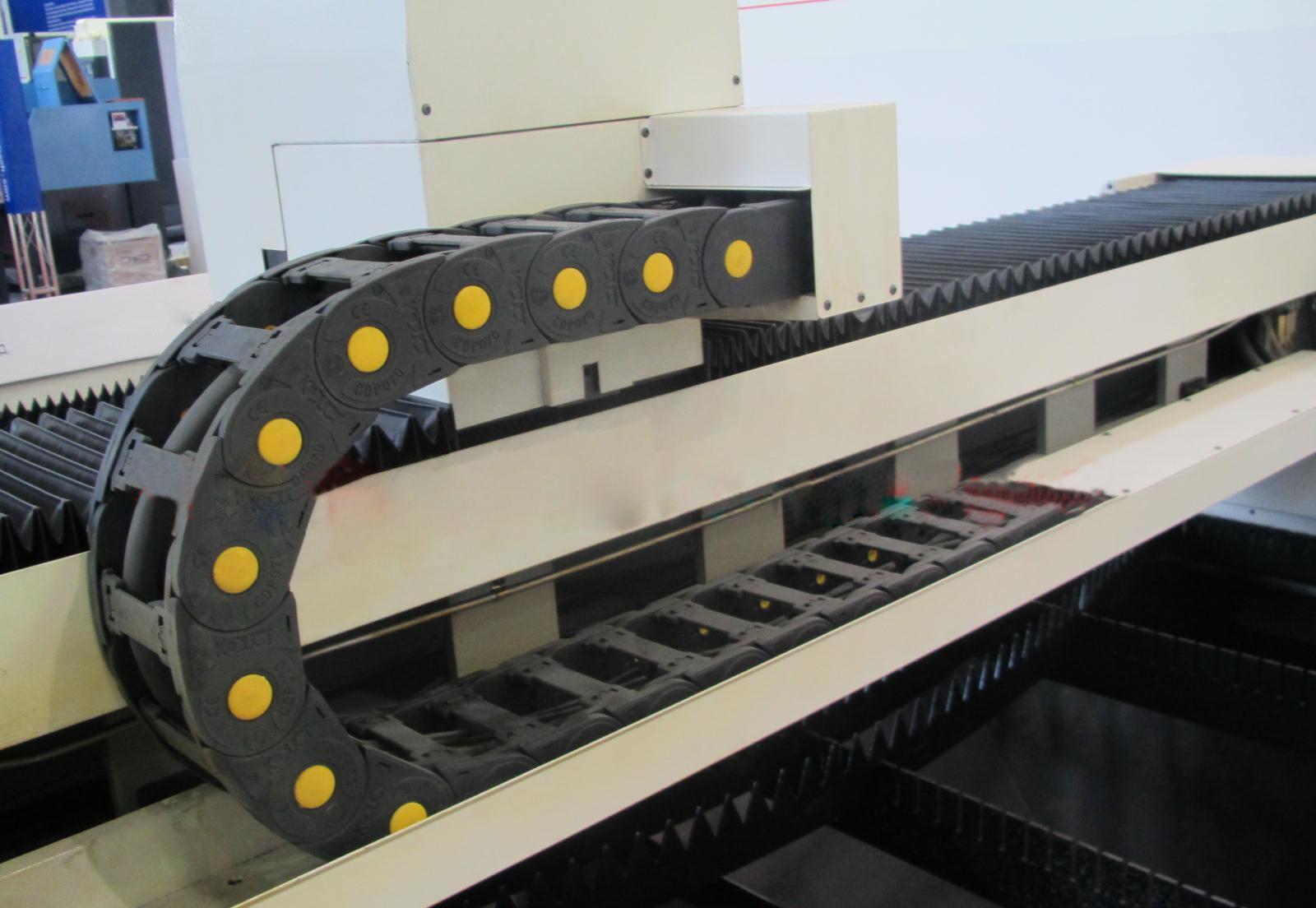

The characteristic of plastic drag chains is that each section can be opened, making it easy to install and repair. They have low noise during movement, are wear-resistant, and can move at high speeds.

At present, tracked plastic drag chains were born earlier than dust-free flexible drag chains, and have been widely used in CNC machine tools, electronic equipment, stone machinery, glass machinery, door and window machinery, injection molding machines, robotic arms, lifting and transportation equipment, automated warehouses, and so on.

What are the main parameters of tracked plastic drag chains and what factors need to be considered when selecting plastic drag chains? How to select plastic drag chains?

1. Determine the inner height of the drag chain: Select the thickest one among the built-in cable ducts, gas pipes, water pipes, etc. as the reference height, and add at least 10% of the height space as the inner height of the tracked plastic drag chain. If the actual height after stacking is used as the reference height value for tracked plastic drag chains.

2. Determine the inner width of the drag chain: Select thicker cables, oil pipes, gas pipes, water pipes, etc., and use the sum of their outer diameters as the reference value for the inner width of the tracked plastic drag chain, leaving at least 10% of the width space.

3. Determine the bending radius of the drag chain: Select the maximum bending radius among the built-in cables, oil pipes, gas pipes, water pipes, etc. as the reference value, and leave more than 10% space.

After a basic understanding of the selection of tracked plastic drag chains, what are the precautions for placing drag chains?

Firstly, there should be 15% remaining space left so that the built-in cables, oil pipes, etc. can move freely and there is no tension on the tracked plastic drag chain in the radial direction.

Secondly, wires of different diameters and sizes should be laid separately to ensure uniform weight distribution. If necessary, physical separation can be carried out using partition plates to avoid wire deviation.

Finally, it should be emphasized that in high-speed or high-frequency operating environments, it is necessary to try to ensure that the wires remain separated from each other horizontally, and not overlap with each other. It is recommended to use spacers when there are many cables, air pipes, oil pipes, etc.